Woven Felts &

Textiles for Charentaise Slippers

As the last manufacturers in the world of woven wool felt for footwear, our know-how and our desire to innovate have enabled the Jules Tournier factory to obtain the Entreprise du Patrimoine Vivant label of excellence for craftsmanship.

Woven with 3 or 5 warps, the thickness of our felts varies between 8 and 14 millimeters.

In addition, today, we produce all the textiles that go into making the slippers—the sole, the sock liner, the faux fur and the upper. While we do not manufacture clothing ourselves, we can supply our customers with all the textiles necessary for making wool slippers.

We can also glue our textiles together to make them double-sided—for example, a woven pure wool side and a faux fur reverse. For each fabric, we offer a range of colors. Our design office also makes every effort to meet your needs. We can adapt our fabrics to your desires and make custom colors for you.

KEYWORDS: accessory, shoe, slipper, Charentaise, non-slip, insulating material, felt, EPV, expertise.

Woven felts for Charentaises: an exceptional craftsmanship

Jules Tournier Manufacturing stands out as the world’s last producer of woven wool felt used for slipper soles. This unique expertise has earned the company the “Living Heritage Company” label, recognizing the excellence of its craftsmanship.

Non-woven and traditional felts: how to recognize them?

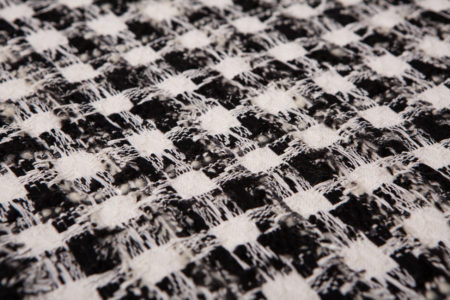

A traditional felt is a woven felt. Unlike non-woven felt, also called needlefelt, traditional felt is produced through the weaving of wool yarns in warp and weft: the felts made by Jules Tournier are traditional.

Technical characteristics of woven felts

Our felts are made with a structure of 3 or 5 warp threads, allowing thicknesses ranging from 8 to 14 millimeters. This variety of thicknesses offers optimal adaptability to meet the specific requirements of the footwear industry, especially for making traditional slippers such as Charentaises.

Unlike non-woven felt, which is made by pressing fibers without weaving, traditional felt is first produced on a loom and then fulled to achieve a dense and soft texture. This process ensures greater durability and comfort.

Our woven felts are primarily used for manufacturing Charentaises, slippers and other indoor shoes. Their structure allows them to provide warmth, comfort and durability, while maintaining a refined aesthetic appearance.

All our woven felts are manufactured in our workshop in Mazamet, in accordance with traditional craftsmanship methods and with particular attention paid to the quality of materials and finishes.

Visit Our Workshops

In the Weaving Workshop, fancy weaves are woven on special loom assemblies where the reeds, the threading, and the knotting are determined by the variations of thread sizes present in each fabric. These technical specificities give our articles all their richness.

Traceability

A fully vertically integrated company, we are experts in and control all stages of manufacturing, from the selection of raw material to the finished fabric.

Quality Control

ISO 9001 certified, we carry out testing at each stage of manufacturing of our fabrics.

Made in France

Located in the Tarn since its creation in 1865, the workshops of the Jules Tournier factory are spread over several production sites in the municipalities of Mazamet, Aussillon, and Pont de l’Arn.

This arrangement guarantees you MADE IN FRANCE production