– WHO ARE WE? –

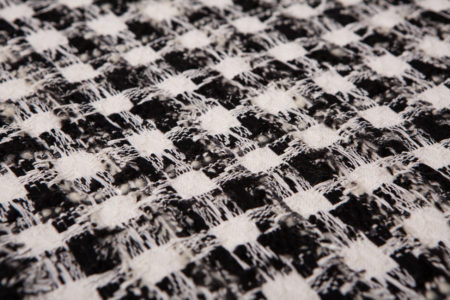

As an independent, family-owned company, we create and manufacture yarns and fabrics for luxury ready-to-wear, and technical fabrics for Personal Protective Equipment (PPE) and industry.

One of the last fully vertically integrated French wool manufacturers, we control all stages of manufacturing, from the selection of raw fiber to the finished fabric.

Our expertise and our creativity are recognized by our customers in France and abroad and distinguished by the label “Entreprise du Patrimoine Vivant” since 2015.

Pierre Bonneville, Lionel Bonneville, Vincent Bonneville

– A little bit of history –

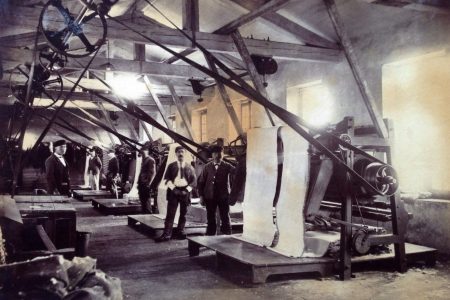

The history of the Jules Tournier factory began in 1865 with its founder, Jean Pierre Etienne Jules Tournier. He was heir to a line of textile manufacturers and traders that can be traced back to the 14th century. He worked with his son, Alphonse, who would take over as head of the company.

In 1895, Madeleine Tournier—the daughter of Alphonse Tournier—married Paul Bonneville. This was the third generation of the family to run the business. Their sons, Jacques and Pierre, perpetuated the family tradition, followed by Claude and Alain, the children of Jacques.

In the 1970s and 80s, the factory bought the archives of the company Blin & Blin as well as those of the Castraise fancy fabric producer Viala. This was a turning point in the history of Jules Tournier, as the company now developed fancy tweeds and created a technical fabric manufacturing department.

At the end of the 1990s, the 6th generation of the family took over the company. Lionel, Pierre, and Vincent succeeded their fathers in managing the factory.

Under their leadership, the Jules Tournier teams produce, develop, and invent new textiles with the same passion that has lasted for over 155 years.

A beautiful family history whose expertise was recognized with the Entreprise du Patrimoine Vivant label in 2015.

– dates –

1865

The Jules Tournier factory is created

1875

Jules Tournier produces “horizon blue” woolen sheets for the French army

1914

The technical fabrics department is developed

1981

Fancy tweed collections are developed after the purchase of the archives and knowledge of the Viala brand

2007

Investments in the company Plo-Ennoblisseur signify the beginning of a lasting partnership

– Our team –

Clément - Weaving Workshop

Clément has worked at Jules Tournier for 3 years as a foreman and loom adjuster. From setting up the loom to fine-tuning it, he makes all the mechanical and technical adjustments needed to ensure quality production.

Gaël - Knitting Workshop

Gaël has been a machine operator in the Knitting Workshop for 3 years. After the pieces of fabric are knit, they pass through different machines—the shearing machine, the ironing machine, the tumbler, the stenter, and the inspecting machine—to improve their appearance.

![]()

It’s a versatile and varied job, where every day the tasks and the machines required are different.

![]()

Pierre - Finishing Workshop

Pierre has worked at the factory for 35 years; he took over his father’s job in the Textile Finishing Workshop. He is responsible for wet finishes and the monitoring of garment-dyed fabrics at the factory.

![]()

It is experience that allows us to make the right decisions when faced with the challenges we encounter and the new products developed.

![]()

Audrey - Office/Administrative

Audrey has worked for Jules Tournier for 13 years. After beginning in accounting, she resumed her studies to train in human resources and joined HR in 2016 upon her graduation.

![]()

For me, Jules Tournier is the company that noticed me and helped me grow.

![]()

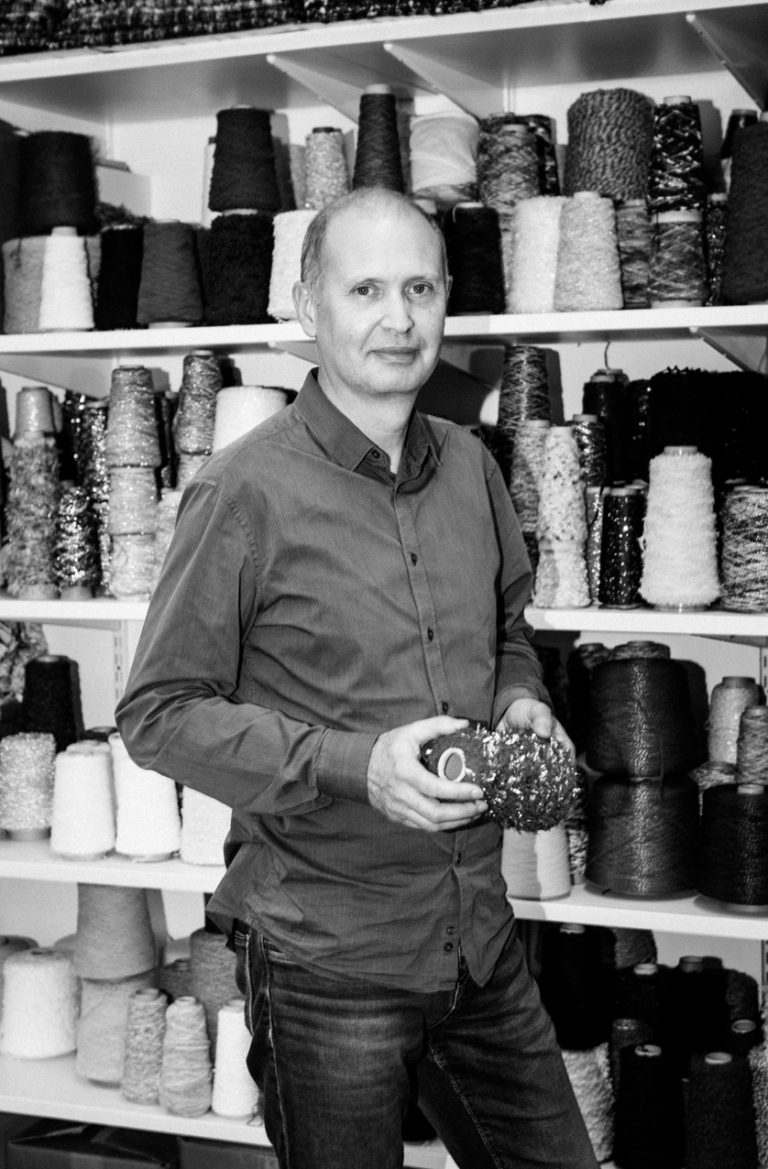

Claude - Weaving Creation & Manufacturing Studio

Claude has been with Jules Tournier for over 31 years. As manufacturing manager of the company, he is in charge of the Weaving Workshop. From the style office to the end of production, he is involved in all stages of the creation of our fabrics.

– Our team–

Clément– Weaving Workshop

Clément has worked at Jules Tournier for 3 years as a foreman and loom adjuster. From setting up the loom to fine-tuning it, he makes all the mechanical and technical adjustments needed to ensure quality production.

Gaël– Knitting Workshop

Gaël has been a machine operator in the Knitting Workshop for 3 years. After the pieces of fabric are knit, they pass through different machines—the shearing machine, the ironing machine, the tumbler, the stenter, and the inspecting machine—to improve their appearance.

“It’s a versatile and varied job, where every day the tasks and the machines required are different.”

Pierre– Finishing Workshop

Pierre has worked at the factory for 35 years; he took over his father’s job in the Textile Finishing Workshop. He is responsible for wet finishes and the monitoring of garment-dyed fabrics at the factory.

“It is experience that allows us to make the right decisions when faced with the challenges we encounter and the new products developed.”

Audrey – Office/Administrative

Audrey has worked for Jules Tournier for 13 years. After beginning in accounting, she resumed her studies to train in human resources and joined HR in 2016 upon her graduation.

“For me, Jules Tournier is the company that noticed me and helped me grow.”

Claude– Weaving Creation & Manufacturing Studio

Claude has been with Jules Tournier for over 31 years. As manufacturing manager of the company, he is in charge of the Weaving Workshop. From the style office to the end of production, he is involved in all stages of the creation of our fabrics.